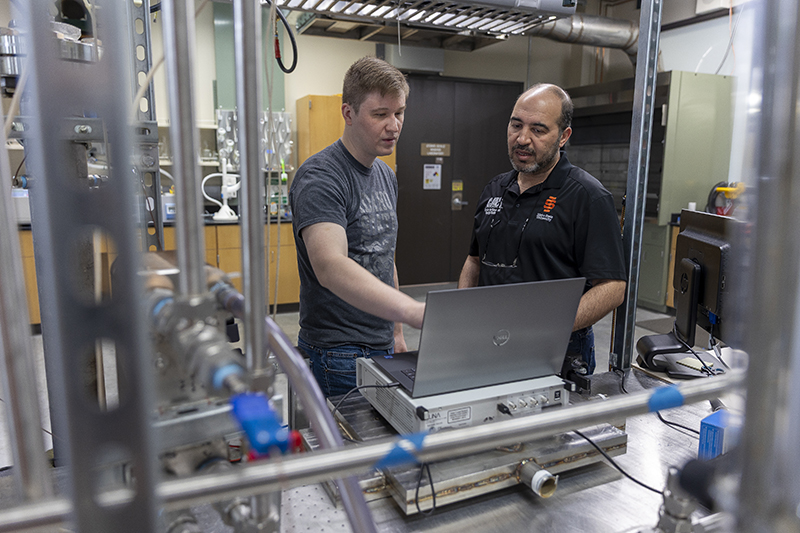

Efficient Exchange: Professor Looking to Develop Next-Gen Heat Exchangers

June 2, 2025

Heat exchangers may not be the first thing that springs to mind when it comes to efficiency, but an Idaho State University engineer is looking to create a new design of the humble part that could be a game-changer for everything from HVAC systems to advanced nuclear reactors.

“A heat exchanger is a device that exchanges heat energy between two different media, such as a liquid, and allows for efficient energy use,” said Amir Ali, associate professor of nuclear engineering at Idaho State and an expert in thermal hydraulics.

While they all do the same basic thing – like cooling or heating a liquid – heat exchangers come in many different shapes and sizes, depending on where they are used. With names like shell-and-tube, double-pipe, plate, and more, they’re found everywhere in the items we use each day, like heaters, air conditioners, and refrigerators, to commercial-sized applications in oil refineries, water treatment plants, food processors, and more.

“Your cell phone, desktop computer, car air conditioner, and water heater at home are some of the things you use daily that have heat exchangers to help cool them down,” said Ali.

Thanks to a grant from the Idaho State Board of Education’s Higher Education Research Council and its Idaho Global Entrepreneurial Mission program, Ali’s new research project will focus on the plate-style heat exchanger, where liquid flows through a series of channels encased in a plate to get it to the right temperature. While simple in concept, engineers like Ali are always looking for ways to improve their design. Heat exchangers can clog up depending on what’s flowing through them, plus, there’s always room to squeeze more efficiency out of the devices. In recent years, modern manufacturing methods have made it possible to create exotic and intricate configurations of heat exchangers.

“New manufacturing technology, such as 3D printing, allows us to build complex heat exchanger channel shapes that are miniaturized in size,” said Ali. “This high level of precision is impossible to achieve with traditional machining tools such as lathes and milling machines.”

To accomplish his task, Ali will first review the existing data and perform a fair amount of math to determine the precise geometric shape for the channels, the number of channels to use, and more to determine what the prototypes will look like. Ali plans to utilize the high-performance computing capabilities at Idaho National Laboratory to analyze and select three designs. After that, it’s on to prototyping. Ali will have models of the three selected designs made and tested for their pressure rate, flow rate, temperature, and other variables to choose the design best suited for further testing.

“We should have solid data on the new technology's efficiency and a range of design parameters which will prove the concept and prepare for further development,” Ali said.

If all goes according to plan, Ali will have enough data to support efforts at commercializing the design and proceed to large-scale tests in future years. The global market for heat exchangers is projected to grow to around $35 billion by 2032, according to Fortune Business Insights.

“The market is looking for the types of features we are looking to optimize,” said Ali, “and our work can help further position ISU as an innovator in Idaho’s energy economy.

“A healthy and growing innovation ecosystem supports the vitality and progress of our communities,” said Marty Blair, vice president for research and economic development at Idaho State. “ISU is committed to supporting innovation as it provides jobs and stability that we all benefit from.”

For more info on Idaho State University’s Department of Nuclear Engineering, visit isu.edu/ne.

Prospective students can book a campus tour at isu.edu/visit.

Categories: