Idaho State University one of a few to implement 3D bioprinting

November 20, 2020

Researchers employ innovative technology in drug research

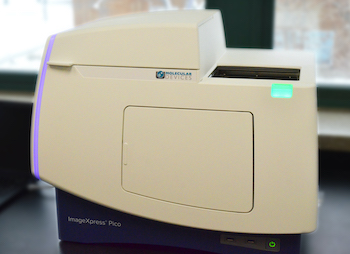

POCATELLO – Cells are multiplying all around us, but at Idaho State University, it’s happening a little differently. ISU is one of the few higher education institutions in the country to receive a 3D printer for the purpose of bioprinting.

Bioprinting is the use of 3D printing technology to print or reproduce a material made up of viable living cells. With this technology, researchers and scientists can print skin, and several other structures that imitate natural human tissue. Cells and other matter from cultured human tissue are transferred into “ink” cartridges, and while it may look like a regular computer printer, such printers are capable of printing different layers with different materials simultaneously.

Jared Barrott, assistant professor in the College of Pharmacy’s Department of Biomedical and Pharmaceutical Sciences and graduate students, Sarah Luelling, Chris Nartker, and Matt Kirkham, are taking part in this groundbreaking technological advancement within the medical research community. Barrott saw the exact 3D bioprinter model they have now at a conference, as it was demonstrating how to print an actual human nose. The 3D printer was issued to the College of Pharmacy, in hopes of making university research more translational, or deliverable, in clinical trials. The basic petri dish environment is not as efficient or accurate in recreating an environment for testing new drugs. Barrott is using the printed materials to help bridge the gap between testing and administering of new drugs.

Partnered with hospitals, the researchers receive tumors removed from patients in the oncology unit. The excess tumor is then acquired for lab use and testing at ISU. Essentially, the tumor is split into a number of smaller tumors and housed in an environment that has been produced by the 3D printer, where it will then receive the proper conditions to remain alive and viable such as temperature, oxygen and carbon dioxide levels, and nutrients. Then, FDA approved cancer drugs are administered to each of the tumors to test which drug is most successful. Physicians can then receive permission to administer such drugs to patients with various stages and types of cancer. Such processes are revolutionizing the way we find new drugs that are successful in treating many diseases. It is a hybrid of both being less expensive high throughput testing and the most relevant to the natural setting of tumors and cells.

Partnered with hospitals, the researchers receive tumors removed from patients in the oncology unit. The excess tumor is then acquired for lab use and testing at ISU. Essentially, the tumor is split into a number of smaller tumors and housed in an environment that has been produced by the 3D printer, where it will then receive the proper conditions to remain alive and viable such as temperature, oxygen and carbon dioxide levels, and nutrients. Then, FDA approved cancer drugs are administered to each of the tumors to test which drug is most successful. Physicians can then receive permission to administer such drugs to patients with various stages and types of cancer. Such processes are revolutionizing the way we find new drugs that are successful in treating many diseases. It is a hybrid of both being less expensive high throughput testing and the most relevant to the natural setting of tumors and cells.

After the 3D tests, the treatment must be validated in clinical trials, but the translation is predicted to be more efficient. Ali Habashi, assistant professor at ISU is also using the technology to print new bones and cancer cells, and then administering cancer-fighting drugs. It is common for breast cancer to travel into the bones, so Hibashi is hoping to use this newfound technology to combat the metastatic condition.

This is the first 3D bioprinter to come to ISU, as well as one of a few bioprinters obtained by universities throughout the country. It has a number of uses applicable for medical technology, including a printable patch that contains drugs itself as a way of administering medication and treatment to patients. Researchers are looking forward to implementing new treatment methodologies and are eager to uncover what else they can learn and discover from this innovative technology.

Categories: