Idaho State University nuclear reactor turns 50

August 13, 2015

POCATELLO – It’s been converting matter to create energy for 50 years and could keep running without any new fuel for more than 200 years.

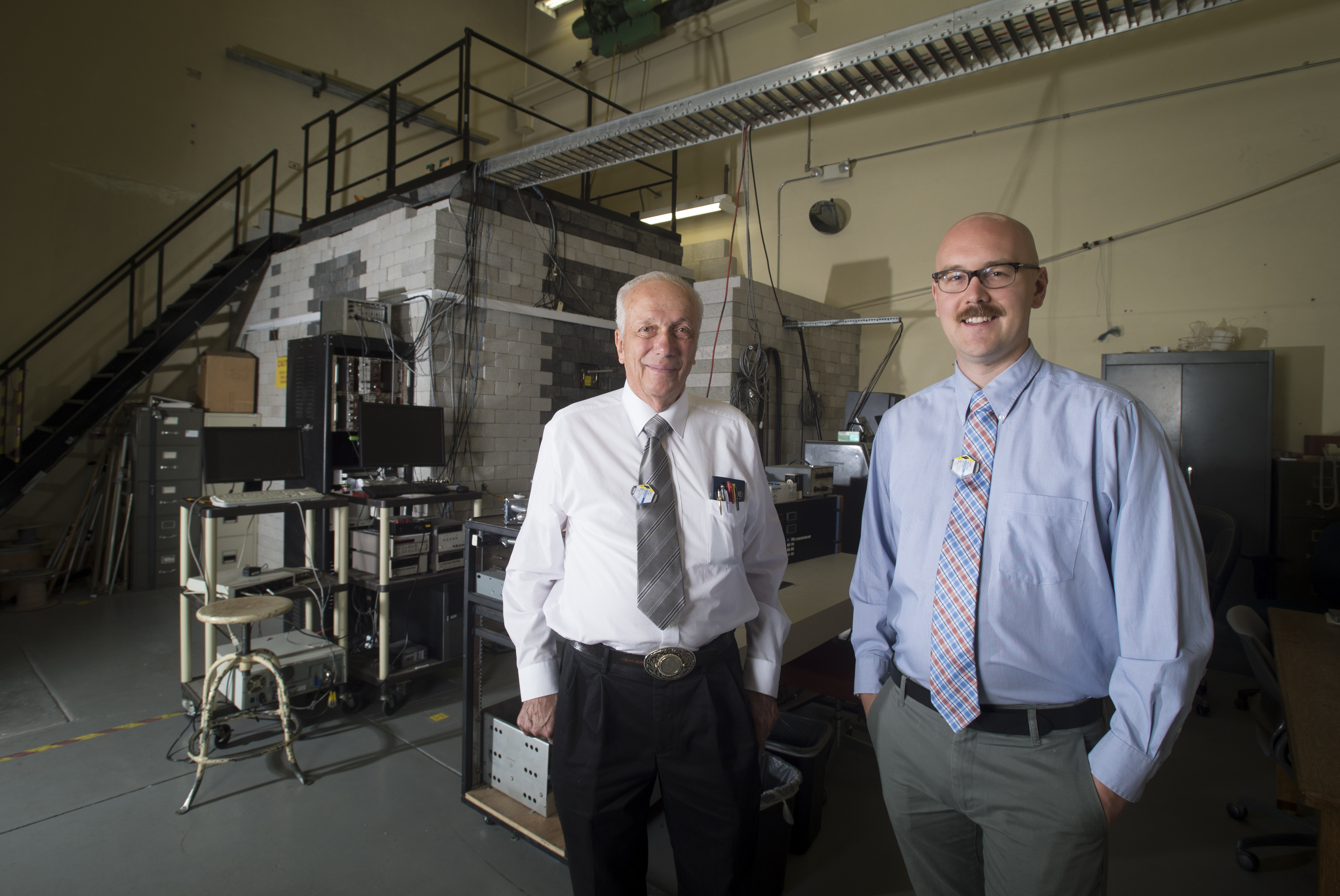

Idaho State University’s AGN 201 Nuclear Reactor is celebrating its 50th year of operation on the ISU campus, providing unique learning and research opportunities for students, faculty and staff, and inspiring awe in some.

“In my personal opinion, the fissioning of the uranium nucleus is the most impressive advancement we’ve made in the past 100 years – nuclear reactors are not yet 100 years old,” said Adam Mallicoat, ISU reactor operator, referring to producing nuclear energy. “The fact that we are able to destroy matter to make energy, for that reason alone, they are the most fantastically interesting applications. They make E=mc2 a workable reality for power production.”

“It is a great training reactor and ultra-safe,” said Jay Kunze, ISU nuclear engineering professor and reactor administrator for the ISU Engineering Nuclear Reactor Office. “It serves to teach students how to operate a reactor, how to design them and how to operate them safely. It serves all the purposes for practical training”

ISU originally received the reactor from the Idaho National Laboratory in 1965 and it was set up in the old ISU Engineering Building, since demolished. It was moved to the new building in 1969 or 1970.

The AGN 201 consists of a reactor unit and a control console. The reactor unit is composed of a central sealed cylindrical core can containing the nuclear fuel material enclosed in a nearly 8-inch-thick graphite reflector, which is surrounded by a nearly 4-inch-thick lead shield, followed by a more than 21-inch-thick water tank for shielding against radiation.

The reactor is licensed for only an extremely small amount of power.

“The energy generated wouldn’t even power a night-light bulb,” Mallicoat said. “It actually only generates 5 watts of heat, that isn’t generated into electricity, it is a negligible amount of energy.”

Though it only produces a small amount of energy, it is a powerful teaching tool.

“Our students get to work with a real reactor and interact and handle real fuel, obviously while supervised,” Mallicoat said. “This is a very hands-on, unique experience that a lot people don’t even get who are working in the field. I’ve known people who have gotten Ph.D.s in nuclear engineering and they have never touched nuclear fuel.

“We don’t run coolant in it like in the bigger reactors where different complexities come in,” he continued, “but the process and the way you go about generating energy is exactly the same, and the way the reactor responds is exactly the same. That is why we can do research and educational experiments at a low power level.”

Annually in the United States, about 300 people are certified as reactor operators. This spring, five undergraduates at ISU were certified as reactor operators.

Interest in nuclear energy is on the upswing nationwide and at ISU, despite the fact five power reactors in the United States have been shut down in the last three years, leaving 99 operating with five being built. Enrollment in ISU’s nuclear engineering program is up about 50 percent in recent years.

Mallicoat also emphasized how safe the reactor is. In the main reactor room on the other side of the shielding walls, levels of radiation are low, “the same levels as your kitchen.” Despite the low levels, students and other visitors are checked before and after entering the laboratory with a radiation dosimeter and strict safety protocols are in place, similar to those that exist at power plants.

“We have to check every single safety mechanism everyday when we run it,” Mallicoat said. “We use so little uranium that it is not a threat. The reactor uses very close to the minimum amount of material you could possible use to make a reactor.”

Categories: